Container Dormitory

A prefab container dormitory solution for the construction site or permanent camp. Not just a temporary container dormitory building, our container dormitories are also practical in areas where traditional buildings are not suitable.We provide perfect residential solutions to our clients in various fields.

Our container dormitories are the perfect solution for quickly establishing comfortable accommodations in areas such as Tier-1 construction sites, remote mining camps, and those affected by natural disasters. The main body of each unit is made up of an ISO-standard galvanized steel frame, which guarantees the stability of a multi-story structure (maximum of 3 levels) and a lifespan of more than 20 years.

Standard configurations include the installation equipped with the totally integrated HVAC, fire-rated insulation (Rockwool/PIR), and the factory-wired/plumbed systems that meet safety standards of different parts of the world (CE/AS/NZS). Although our principal fleet has 20ft (6058 x 2438mm) and 40ft (12192 x 2438mm) footprints, the engineering team offers custom modular configurations to facilitate the integration of such specialized zones as executive offices, command centers, and industrial-scale dining halls.

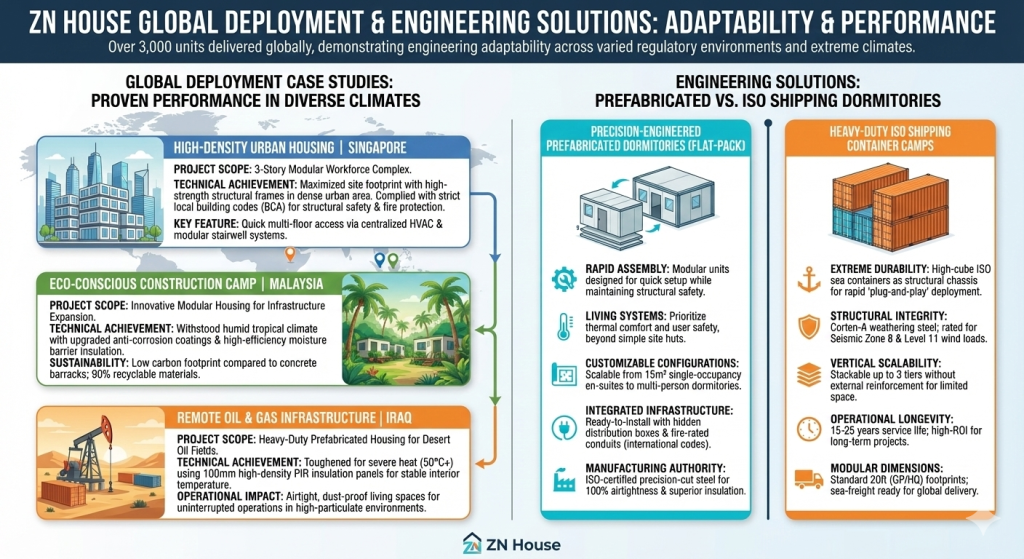

Engineering Solutions: Prefabricated vs. ISO Shipping Dormitories

Precision-Engineered Prefabricated Dormitories (Flat-Pack)

Our Prefabricated Dormitory systems represent a high-performance solution through modular units, which are specifically designed to be rapidly put together while maintaining structural safety. In contrast to simple site huts, these units are merged “living systems” that, above all, take into account the thermal comfort and safety of the users.

Customizable Configurations: Designed to be scalable, the spatial organization can be varied from 15m² single-occupancy en-suite rooms (with integrated wet-cells) to densely populated multi-person dormitories.

Integrated Infrastructure: Electrically and data-wise, each unit is a ready-to-install model and is equipped with the distribution boxes that are hidden and the fire-rated ducts that conform to the international building codes.

Manufacturing Authority: Being an ISO-certified manufacturer, ZN House employs precision-cut steel components for the purpose of achieving 100% airtightness and a higher level of insulation as compared to the traditional structures.

For concerts, sports tournaments, or cultural festivals hosting thousands, our prefab dormitories provide scalable, temporary living spaces for staff, volunteers, and performers. Modular container housing units can be configured into multi-story complexes with shared kitchens, laundry facilities, and security systems, offering a hotel-like experience in temporary settings. The lightweight, flat-pack design of our dormitory containers minimizes shipping costs, while quick assembly (3–5 days for 100+ units) ensures readiness before event kickoff. Post-event, modules can be disassembled and relocated, making them a sustainable choice for recurring events.

Heavy-Duty ISO Shipping Container Camps

When extreme durability and rapid ‘plug-and-play’ deployment are essential, our Shipping Container Dormitories are powered by high-cube ISO sea containers as the structural chassis.

Structural Integrity: Made from Corten-A weathering steel, these units perform top of the line in bending and compressive strength. They are rated for Seismic Zone 8 and can withstand Level 11 wind loads.

Vertical Scalability: Our shipping container modules, which have been optimized for very limited space sites, are capable of being stacked vertically up to 3 tiers without the requirement of additional external structural reinforcement.

Operational Longevity: Our ISO-based dormitory conversions offer a service life of 15-25 years, which makes them a high-ROI asset for long-term mining and infrastructure projects, whereas the lifespan of standard modular units is different.

Modular Dimensions: The standard 20ft (GP/HQ) footprints are the units in which these are available, thus providing a rigid, “drop-in” solution that is sea-freight ready for global delivery.

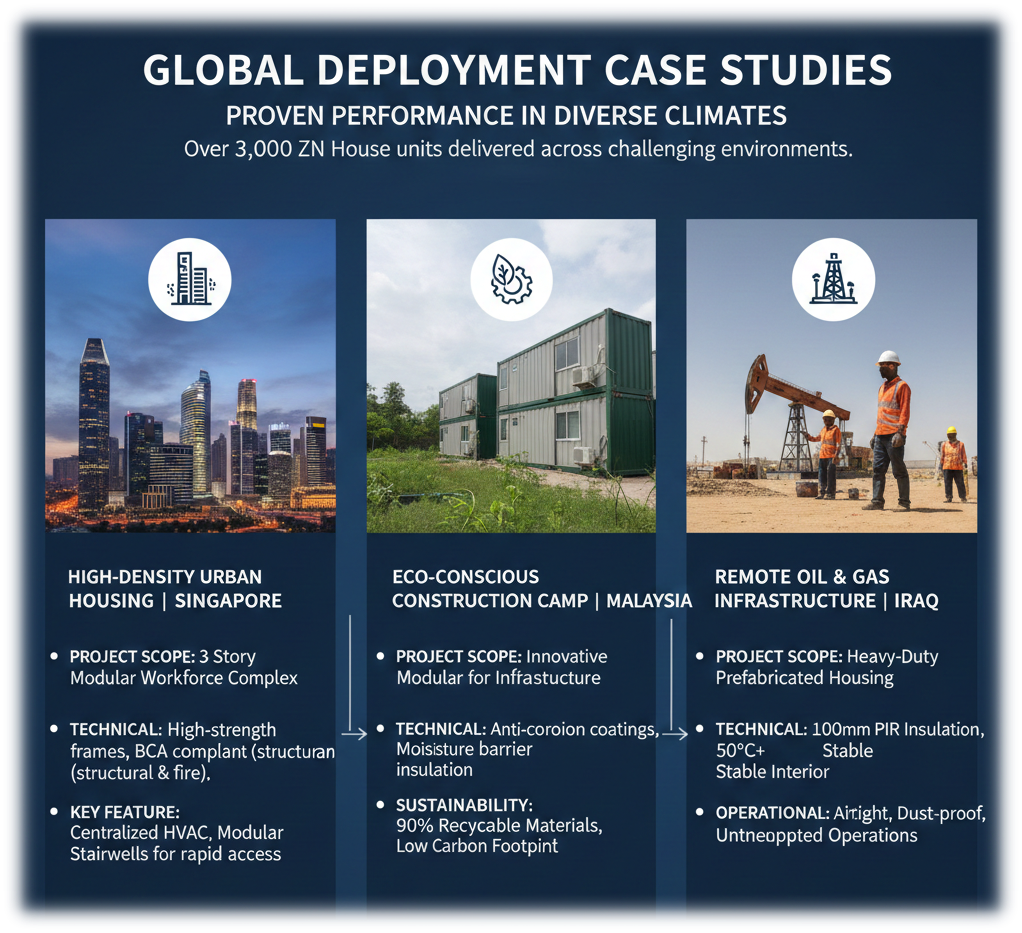

Global Deployment Case Studies: Proven Performance in Diverse Climates

ZN House has successfully delivered over 3,000 units globally, demonstrating engineering adaptability across varied regulatory environments and extreme climates.

High-Density Urban Housing | Singapore

Project Scope: 3-Story Modular Workforce Complex.

Technical Achievement: The project effectively utilized our structural frames, made of high-strength material, to the full extent of the site in a densely populated urban area. The design complied with very strict local building codes (BCA) in terms of structural safety and fire protection.

Key Feature: It enabled quick multi-floor access through the combination of centralized HVAC and modular stairwell systems.

Eco-Conscious Construction Camp | Malaysia

Project Scope: Sustainable Modular Housing for Infrastructure Development.

Technical Achievement: Designed to withstand challenging conditions like a humid tropical climate, these homes come equipped with upgraded anti-corrosion coatings and a highly efficient moisture barrier insulation.

Sustainability: The project has a very low carbon footprint compared to the conventional concrete barracks, which is achieved by the fact that 90% of the materials used are recyclable.

Remote Oil & Gas Infrastructure | Iraq

Project Scope: Heavy-Duty Prefabricated Housing for Desert Oil Fields.

Technical Achievement: The modules were toughened up for the severe heat of the Middle East by the use of 100mm high-density PIR insulation panels to keep the inside temperature stable in 50°C+ areas.

Technical Achievement: The modules were toughened up for the severe heat of the Middle East by the use of 100mm high-density PIR insulation panels to keep the inside temperature stable in 50°C+ areas.

Deployment Scenarios & Operational Specifications

ZN House modular systems are engineered for three core industrial applications, each optimized for specific logistical and regulatory requirements.

Industrial & Construction Workforce Camps

Scale: Modular clusters are planned for personnel ranging from 50 to 1,000+.

Deployment Speed: The 50-unit camp can be structurally put together and made weather-tight from the site delivery within 72-96 hours.

Technical Compliance: The frames and interiors are designed to comply with OSHA and HSE (Health, Safety, and Environment) standards, and they come with fire-rated Class A1 insulation and anti-slip flooring in high-traffic wet areas.

Key Advantage: The pre-integrated “Plug-and-Play” utility connections (Electrical/Sewage) make it possible to be occupied immediately after levelling.

Event Infrastructure & Logistics Support

Configuration: To fully take advantage of the very small surface area around stadiums or in the remote areas of a festival grounds, the units are stacked in a high-density, multi-story way (up to 3 levels).

Logistical Efficiency: By using our Flat-Pack design, it is possible to load up to 4 units in a single 20ft ISO-bundle, and thus the inland freight costs are reduced by 75%.

Operational Features: Sound-dampening wall panels and smart-card access control systems for staff or artist accommodations with a high turnover can be installed in the units.

Rapid Response Disaster & Humanitarian Relief

Mobility: The Special Foldable Container concept for the collapsible shelter basically brings the 450mm height back; thus, it is possible for one single truck to carry 6-10 shelters at the same time.

Resilience: These buildings have been designed to meet the requirements of the Seismic Category 8 and can resist wind forces of up to 120mph, thus ensuring a safety factor higher than that of the tent-based emergency relief solution.

Humanitarian Standards: These shelters meet the requirements of The Sphere Handbook in terms of area per person and come with built-in solar-ready roof mounts and gravity-fed water filtration that can be connected.

Engineering Excellence for Global Environments

Either for arctic mining utilizing R-30 rated insulated units or for high-ventilation tropical modules for Southeast Asian infrastructure projects, ZN House guarantees that each dormitory is a turnkey asset. Within 48 hours of a project consultation, we deliver complete General Arrangement (GA) drawings and loading plans.

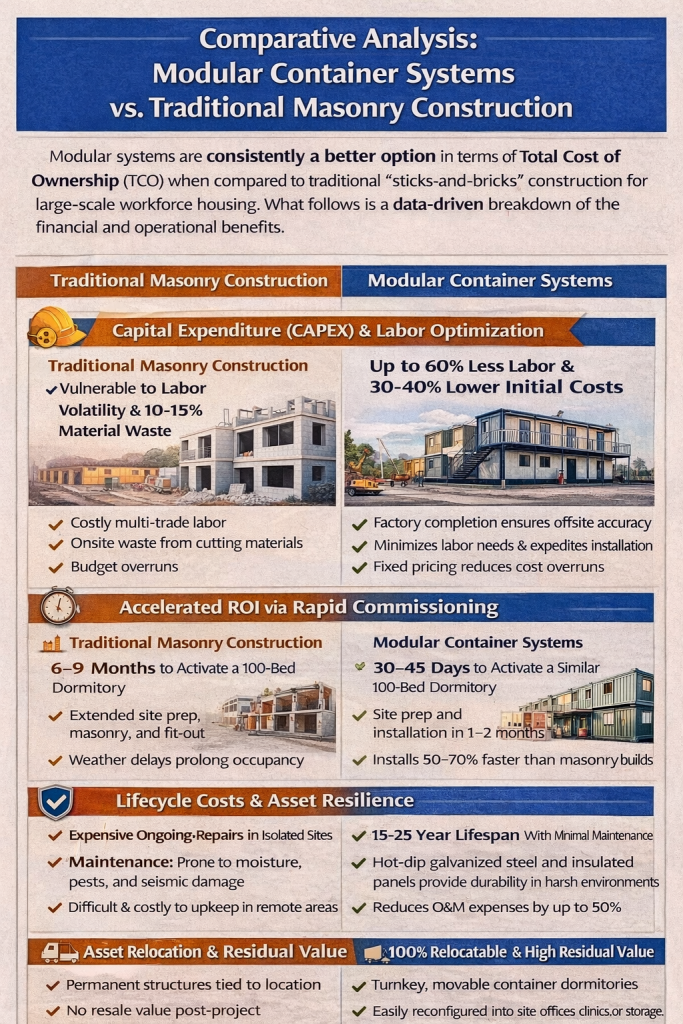

Comparative Analysis: Modular Container Systems vs. Traditional Masonry Construction

Modular systems are consistently a better option in terms of Total Cost of Ownership (TCO) when compared to traditional “sticks-and-bricks” construction for large-scale workforce housing. What follows is a data-driven breakdown of the financial and operational benefits.

Capital Expenditure (CAPEX) & Labor Optimization

Traditional building is vulnerable to changing labor costs at the site and material that is wasted (averaging 10-15%).

The Modular Advantage: Our prefabricated dormitory units are 80-90% completed in a factory-controlled environment. This industrial accuracy brings a reduction in the requirement of the onsite labor up to 60% and lowers the total initial construction expenses by 30-40%.

Budget Predictability: Factory fixed pricing puts an end to the “budget creep,” which is typical of a traditional construction that may be affected by weather delays or local material shortages.

Accelerated ROI via Rapid Commissioning

Time-to-occupancy is one of the most important measures of the financial performance of any mining or construction project.

Timeline comparison: A conventional 100-bed dormitory normally takes 6-9 months for site preparation, masonry, and fit-out, whereas a ZN House Container Camp of a similar size can be put into operation within 30-45 days.

Operational Continuity: On top of that, the quick installation makes it possible to bring the crew on the ground earlier, thereby directly resulting in the client’s project timelines and revenue increasing at a faster rate.

Lifecycle Costs & Asset Resilience

Traditional architectures that are located in isolated areas or under severe conditions are usually of high maintenance as a result of the penetration of moisture, termites, or seismic settling.

Structural Durability: With the use of hot-dip galvanized Q235B steel frames, our products are capable of providing a 15–25-year service life with almost no structural maintenance.

Maintenance Savings: Steel being non-porous and the use of high-quality sandwich panels eliminates the possibility of mold and structural decay, thus lowering the long-term O&M (Operations & Maintenance) costs by around 50% as compared to timber-framed or low-grade masonry units.

Asset Relocation & Residual Value

Traditional dormitories are “sunk costs” when the project is over, the building no longer has any use.

A Moveable Asset: Our Shipping Container Dormitories are considered equipment/temporary assets, which makes it possible to relocate them 100% to new project sites.

Repurposing: The units can be simply transformed from multi-person dorms to site offices or storage; thus, the investment will have a high residual value for different project lifecycles.

Financial Comparison Summary:

| Metric | Traditional Construction | ZN House Modular |

| Construction Time | 6–12 Months | 4–8 Weeks |

| On-site Labor Requirement | High (Multi-trade) | Low (Assembly only) |

| Mobility | Permanent (Fixed) | 100% Relocatable |

| Material Waste | 10–15% | < 2% (Factory Precision) |

| Depreciation Category | Real Estate (Long) | Equipment/Plant (Accelerated) |

Why Choose ZN House Container Dormitories

When it comes to reliable, versatile housing solutions, ZN House’s container dormitories and modular container housing stand out as leaders in innovation and performance. Here’s why our designs are the preferred choice for construction sites, events, and humanitarian missions:

1. Rapid Deployment for Time-Critical Projects

Time is money in construction—and a lifeline in emergencies. Our prefabricated dormitories are 80% factory-built, reducing on-site assembly to 3–7 days for a 50-person camp. This speed is made possible by modular components like pre-installed electrical systems and insulated panels, ideal for container dormitories in remote locations. For disaster zones, flat-pack shipping container dormitories cut transport volume by 70%, ensuring delivery to even the most inaccessible areas within 48 hours.

2. Durability Engineered for Harsh Environments

Construction sites and disaster zones demand toughness. Our modular container housing uses Corten steel frames with C5 anti-corrosion coatings, capable of withstanding 120mph winds and seismic activity. Insulated with rock wool and double-glazed windows, units maintain comfort in -40°C to +50°C, making them suitable for arctic tundras or tropical storms. Unlike traditional temporary housing, our shipping container dormitories meet international standards (OSHA, ISO 9001), ensuring long-term reliability.

3. Scalable & Customizable Layouts

Every project is unique—our container dormitories adapt accordingly. Start with a 20ft unit for 4–6 people, then expand to multi-story complexes for 2000+ residents using stackable modular container housing designs. Customize layouts with private cabins, shared kitchens, or even medical facilities—all while maintaining standardized quality. For events, add amenities like Wi-Fi zones or security systems; for a construction site, prioritize heavy-duty flooring and anti-theft features.

4. Sustainability & Cost Efficiency

We balance performance with eco-consciousness. Prefabricated dormitories reduce on-site waste by 80%, while 95% of materials are recyclable. Solar-ready roofs and water-saving fixtures cut operational costs by 30% over 10 years. Compared to traditional builds, our container dormitories save 40% on labor and material costs, making them a smart investment for both short-term projects and long-term housing solutions.

Choose ZN House for modular container housing that delivers speed, durability, and sustainability, backed by a decade of expertise in global housing challenges. Contact us to design a custom container dormitory solution for your needs.

Why are Container Dormitories Ideal for Remote or Temporary Workforce Housing?

A container dormitory is the perfect pre manufactured home solution for companies needing quick, scalable, and comfortable accommodation for workers, particularly in remote areas or temporary project sites. These units are essentially off site manufactured homes, meaning they are built in a factory under strict quality control before being delivered fully assembled. This allows for rapid deployment without the need for complex on-site construction, which can be expensive and time-consuming in difficult-to-reach regions. ZN House’s container readymade houses can be set up within days, offering ready-to-use dormitories that include ventilation, lighting, sanitation, and electrical systems.

Moreover, these units are built using robust materials, especially the steel frame manufactured homes structure, which ensures durability and resistance to harsh weather. A typical container dormitory can be customized with beds, storage, private or shared bathrooms, and air conditioning systems. For mining, infrastructure, and disaster relief operations, where housing must be both reliable and mobile, container dorms provide the right mix of practicality and affordability. As leading container home builders, ZN House designs each dormitory to align with international safety and efficiency standards, making it a preferred solution for enterprises with a mobile workforce.

How Customizable are Container Dormitories for Different Workforce Needs?

Engineering Versatility and Spatial Configuration

ZN House employs a state-of-the-art “Building Block” modular philosophy that opens up the possibility of custom architectural layouts, which can vary from densely populated 8-person bunkhouses to luxurious executive en-suites with the integration of wet cells. Our frame is the result of a design that promotes vertical G+2 (three-story) stacking; thus, modular stairwell units and reinforced corridor walkways are the means of enhancing site footprints in space-limited mining or urban construction areas.

Such Off-Site Manufactured (OSM) adaptability is the main reason why assets are not “fixed” to a single purpose; our units can be detached and effortlessly reassembled into command centers, industrial canteens, or Level-2 medical clinics without the need for a structural reinforcement as a project moves from construction to operations.

What are the Environmental Benefits of Choosing Container Homes over Traditional Buildings?

ZN House’s Chinese container homes are an excellent eco-conscious choice. By repurposing shipping containers and manufacturing them into livable, insulated spaces, we reduce raw material consumption and construction waste. These container readymade houses also require less water and fewer emissions during production compared to concrete or brick buildings. Being off site manufactured homes, the units are built efficiently in factories, reducing on-site pollution and construction debris. Energy-efficient options like LED lighting, low-flow plumbing fixtures, and solar-powered systems can be installed to enhance sustainability even further.

Moreover, many of our steel frame manufactured homes are designed for long-term reuse. When a container dormitory is no longer needed in one location, it can be transported to another site, limiting the environmental cost of constructing new housing. ZN House believes in sustainable development, and our role as a responsible container homes manufacturer is to provide not just affordable, durable, and mobile housing—but also to do so with minimal impact on the environment. For companies striving to meet ESG goals, switching to affordable modern prefab homes is a smart, green investment.

Technical Specifications and Environmental Adaptability

Besides the spatial layout, every dormitory represents a high-performance shell that can be tailored to the project’s specific GIS stressors and international compliance regulations. Clients are allowed to define thermal insulation schemes, for instance, from 50mm to 100mm of high-density Rockwool with a Fire Class A1 rating, as well as C5-M marine-grade anti-corrosion coatings for areas exposed to high-salinity coast. All the units have factory-integrated and factory-tested MEP (Mechanical, Electrical, Plumbing) systems conforming to SAA, UL, or CE standards; thus, the term “plug-and-play” deployment is quite appropriate here. ZN House, a combination of hot-dip galvanized Q235B steel frames and solar-ready roof mounts along with anti-slip commercial flooring, therefore, is promoting an environmentally friendly, industrial-grade housing solution that is capable of satisfying both ESG objectives and strict worldwide safety standards.

How Does A Premade Shipping Container House Simplify Project Timelines?

Choosing a premade shipping container house from ZN HOUSE is a game-changing decision for project managers who prioritize speed, efficiency, and quality. These homes are built in a controlled factory environment, where all aspects—from framing to plumbing—are completed prior to delivery. This minimizes the risks and delays typically associated with on-site construction, such as labor shortages, weather conditions, or logistical barriers. Once delivered, the units only require simple placement and utility connections, cutting project timelines drastically. This is particularly beneficial for disaster relief housing, pop-up offices, or any operation requiring immediate use.

The advantage of using a premade shipping container house is not just limited to speed—it also ensures consistency in quality and compliance. Each unit undergoes rigorous quality checks before shipment, ensuring it meets both local building standards and international durability expectations. With design flexibility that accommodates bathrooms, kitchens, and multi-room layouts, these homes are suitable for both commercial and residential purposes. ZN HOUSE’s long-standing reputation for excellence means you’re investing in a product backed by decades of experience. For those seeking awesome shipping container homes with minimum installation fuss, premade is the way to go.

Are 2 Bedroom Prefab Container Homes Suitable for Families or Remote Team Leaders?

Absolutely. 2 bedroom prefab container homes are gaining popularity among families, remote project managers, and even eco-conscious urban dwellers. These homes are specifically designed to maximize usable space while offering all the comfort of a traditional home. With a living area, kitchen, two separate bedrooms, and a bathroom, they provide an excellent balance of privacy and communal living. For companies operating in remote areas, offering such accommodations to team leaders or engineers not only boosts morale but also improves productivity by giving employees a home-like atmosphere.

ZN HOUSE specializes in customizable layouts to suit your unique needs. Whether you want separate entrances, extra windows, or smart storage solutions, these container homes can be adapted accordingly. Their full-steel frames offer strength and security, while high-quality insulation keeps the interior comfortable in any climate. With increasing interest in cool manufactured homes that are both functional and aesthetic, 2-bedroom units from ZN HOUSE stand out. They’re easy to transport, quick to install, and perfect for those who value mobility without compromising on living standards. This makes them an ideal option for both short-term deployments and long-term residence.

How Do Container Dormitories Improve Safety Standards on Job Sites?

Strategic HSE Risk Mitigation and Fatigue Management

As a major part of the administration’s effort to control fatigue, the use of on-site modular housing can greatly lower the chances of fatigue-related incidents and Lost Time Injuries (LTIs) in dangerous sectors. ZN House engineering upgrades the old and poorly ventilated temporary structures with solid structural modules that are equipped with non-combustible Class A-rated insulation and fire-rated door assemblies.

These devices turn into a reliable perimeter security at the work site, thus industrial-grade locking mechanisms and integrated electronic access control are used to prevent unauthorized entry and ensure the safety of the staff and the equipment. Apart from radically reducing the probability of transit-related accidents by doing away with the need of daily commuting through dangerous areas or remote locations, project managers can also be certain of the workforce being within a controlled, OSHA-compliant safety envelope.

Infectious Disease Control and Biosecurity Standards

The modular architecture of ZN House dormitories offers a more effective framework for site biosecurity and infectious disease mitigation that can be easily compared with those of traditional open-plan barracks. Each unit is a separate biological zone in itself, thus enabling quick sectional isolation and controlled personnel density, which is very important for the continuity of operations during public health crises. Our designs incorporate the systems of high-exchange mechanical ventilation to guarantee the best Indoor Air Quality (IAQ) and can be further enhanced with antimicrobial interior surfaces for high-hygiene environments.

This well-organized and controlled system of housing makes site safety not only a policy but also an engineered safety measure, thus providing a high-performance living environment that hardly causes any health-related downtime and is well above international humanitarian and industrial safety standards.

Can A Mobile Home Shipping Container be Relocated Easily after Installation?

One of the standout advantages of a mobile home shipping container is its relocability. Designed with mobility in mind, these units are built on a steel frame that can endure frequent transportation without structural degradation. Whether you’re a construction firm shifting work sites or an NGO providing temporary housing in disaster-struck areas, mobile container homes are the practical, time-saving choice. ZN HOUSE incorporates crane-lift points and modular stacking capability, allowing for easy loading, unloading, and site adaptation.

Beyond mobility, these homes are also built for comfort. Equipped with all the essential utilities and structural insulation, they ensure a livable space no matter where they’re placed. What’s more, these mobile homes can be repurposed for different applications over their lifetime—serving as worker housing on one site and an on-site office on another. With the growing popularity of awesome shipping container homes, a mobile option gives you both flexibility and durability. If your operations demand agility without sacrificing structural integrity, a mobile shipping container from ZN HOUSE is the ideal solution.